3D X-Ray - Services

Part Inspection Lab

We help companies thoroughly investigate

parts & assemblies with our high quality

3D X-ray services paired with

expert analytical support.

PHASE ONE

CONSULTATION

After the initial inquiry, our services begin by having an in-depth discussion with the inquiring individual and interested parties. If the fit is right for our 3D X-Ray services, the feasibility review considers part/assembly type, material, regions of interest, and the objective for the CT scan.

PHASE TWO

SYSTEM MATCHING

We then match the NDT or Metrology inspection need with one of our many and highly diverse CT scanning machines. Our industrial lab utilizes 100kv, 150kv, 225kv, 450kv, and 3MEV linear accelerator CT systems with LDA’s and flat panel detectors.

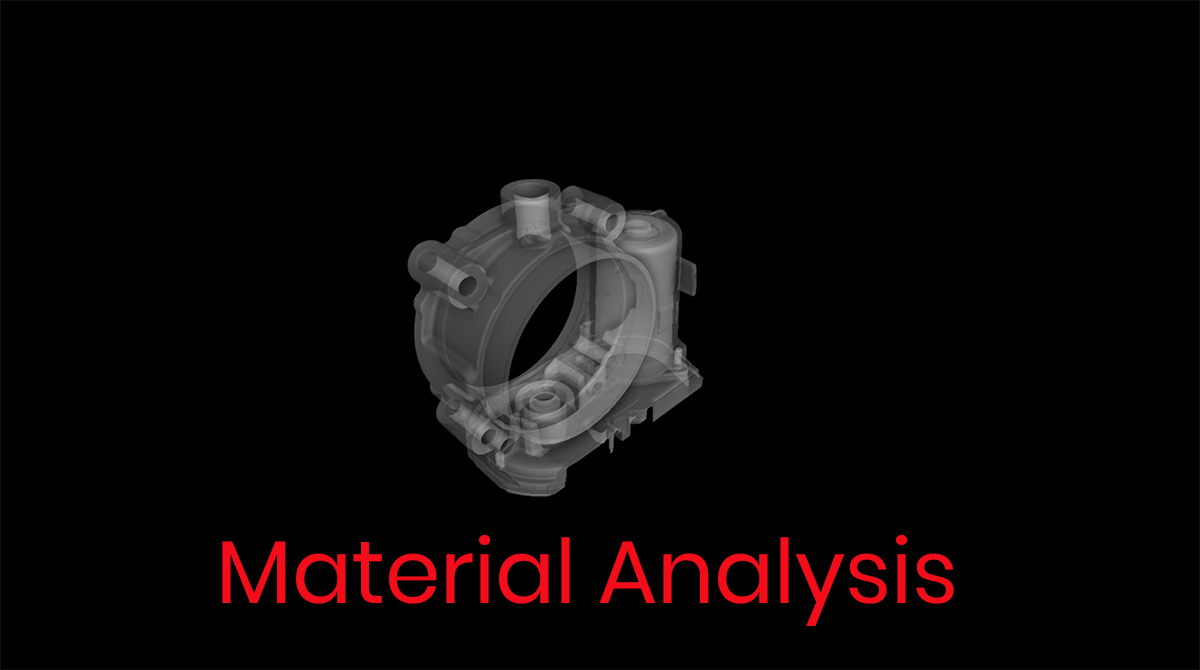

PHASE THREE

ANALYSIS

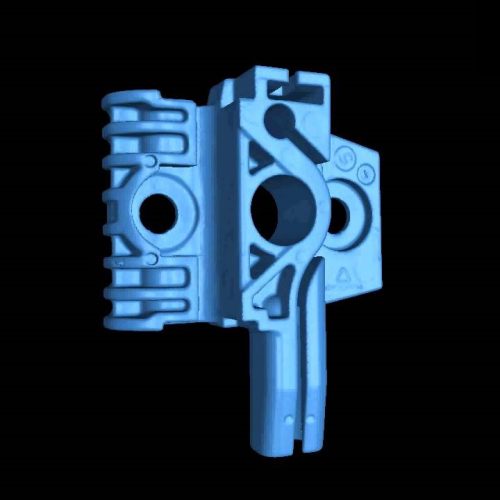

Depending on the 3D x-ray project, we analyze the reconstructed (3D imaging) results for either material or geometry based output requirements.

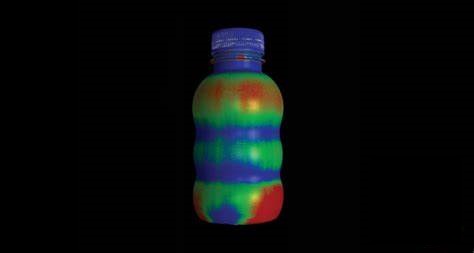

Material reporting is based upon internal density variations or percent volume changes. These types of 3D X-ray analysis include :

Visualizing virtual cross-sectional slices

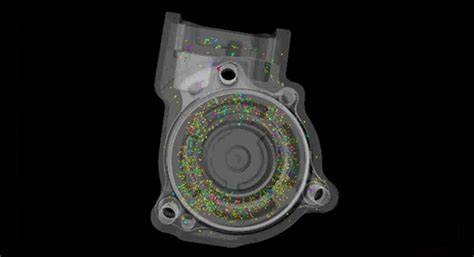

Porosity / Inclusion Analysis (Color coded voids, inclusions, and micro pores by volumetric size or percentage)

Enhanced Porosity (Automotive Industry Specific, P201 – 50097, P202 – 50098, P203 Analysis)

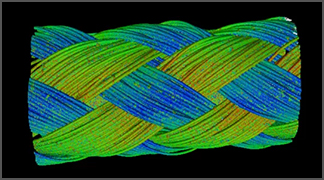

Fiber Analysis (Color coded fiber directional reporting)

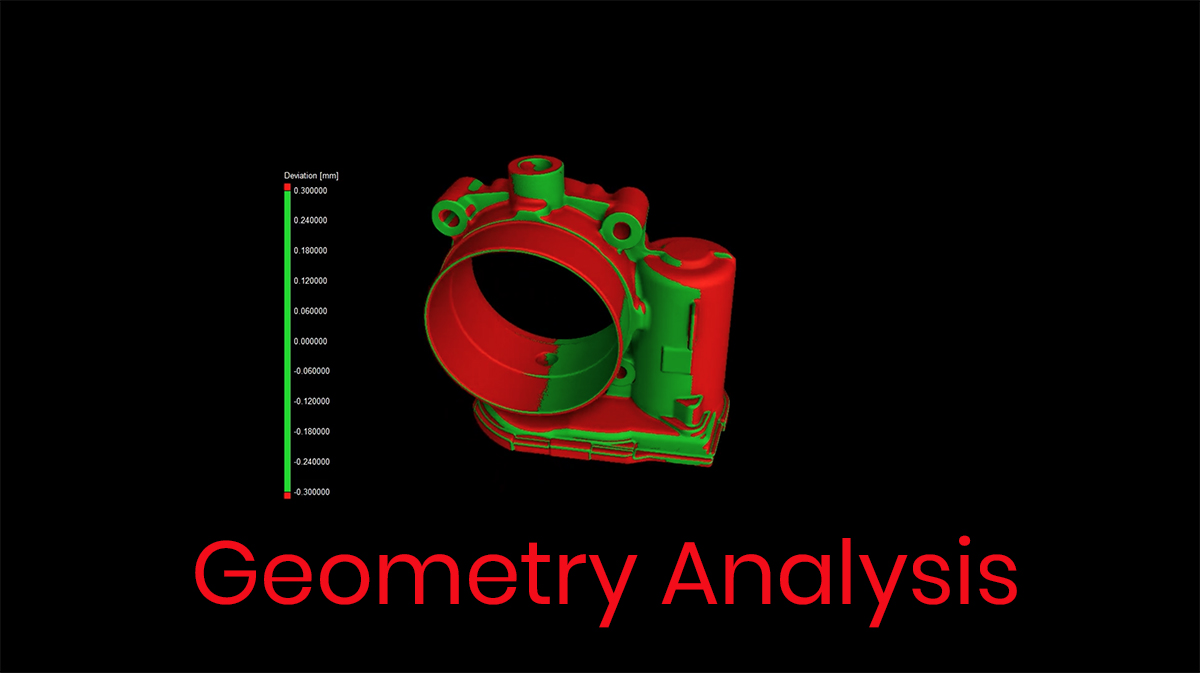

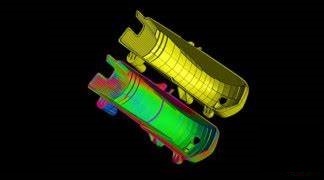

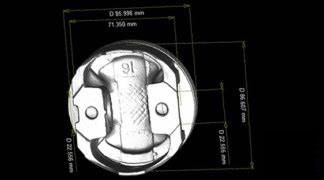

Geometry reporting is based upon measurement variations or dimensioning requirements. These types of 3D x-ray analysis include :

Part to CAD / Part Comparison (Color coded variations from nominal or another identical part. Alignment by: RPS, 3-2-1 alignment, best fit, sequential)

Wall Thickness Analysis (Color-coded results identifying insufficient or excessive wall thicknes)

First Article Inspection (Tolerancing based upon part print dimensions)

Enhanced FAI (AS9102 Form 3 Reporting)

Reverse Engineering (Generation of a STL file with internal & external part geometry)

PHASE FOUR

REVIEW

As all 3D x-ray projects are unique, each project is finalized between our lab and the customers key decision makers over a results web conference. If required, output deliverables can vary between picture files, excel files, presentations, 3D imaging / CT dataset viewing software, or in some cases STL files.

Need more info on 3D X-Ray?

Review our knowledge section below.

Overview

X-ray technology and radiographic techniques have been utilized for quality control purposes in regards to industrial applications for many years. A relatively new form of X-ray is 3D x-ray, where users are able to view 2D x-ray imaging results from different angles of a given part for failure analysis purposes. Users often outsource such testing projects to certified radiographers and nondestructive testing (NDT) labs for a quick and easy part analysis.

What is 3D X-Ray?

3D X-ray is the concept of capturing multiple 2D x-ray images from different angles of a given part. These resulting 2D X-ray images are viewed and analyzed independently for quality control purposes. For a true 3D perspective of a given part, users turn to Computed Tomography (CT) scanning. With 3D x-rays, a parts internal configurations and structural properties are inspected for failure analysis.

How 3D X-Ray Works

With the use of an x-ray source and detector panel, a part can be inspected by analyzing 3D X-ray results. The x-ray source has to be strong enough to penetrate through the material of the part being inspected. As the x-ray source shoots through the part, a 2D x-ray is captured using a detector panel or film screen. Due to technological advancements in digital detectors, film screen applications have become obsolete for industrial inspection purposes. The detector panel captures 2D x-rays of a given part from multiple different angles which are independently viewed and analyzed for quality control and failure investigations.

Uses

3D X-rays can be utilized in many different ways including but not limited to:

- Research and development

- Locate and measure internal fatigue

- Identify discrepancies in part

- Comparison analysis for part structure (perfect vs. defective part)

- Pre-production inspection

- Prototype testing

- Production part approval and rejection

- Quality control management tool

- Failure analysis and investigation

Benefits

There are several benefits for reviewing and analyzing 3D x-ray results, including but not limited to:

- Internal part composition

- View internal interaction between different material

- Identify, locate and measure internal defects

- Highlight fatigues and discrepancies

- Quick, accurate and reduces time

- Nondestructive method of inspection

Applications

Industrial applications for 3D x-ray vary and can be applied across many different industries including:

- Aerospace

- Automotive

- Medical Device

- Military and Defense

- Consumer products

- Packaging

Types

3D x-rays can be conducted with one of three different types of radiography testing (RT) testing techniques. These include:

- Film radiography

- Computed radiography

- Digital radiography