Industrial X-Ray CT - Services

Part Inspection Lab

We help companies thoroughly investigate

parts & assemblies with our high quality

industrial x-ray CT services

paired with expert analytical support.

PHASE ONE

CONSULTATION

After the initial inquiry, our services begin by having an in-depth discussion with the inquiring individual and interested parties. If the fit is right for our industrial X-Ray CT services, the feasibility review considers part/assembly type, material, regions of interest, and the objective for the CT scan.

PHASE TWO

INDUSTRIAL X-Ray CT – SYSTEM MATCHING

We then match the NDT or Metrology inspection need with one of our many and highly diverse industrial X-Ray CT imaging machines. Our industrial lab utilizes 100kv, 150kv, 225kv, 450kv, and 3MEV linear accelerator CT systems with LDA’s and flat panel detectors.

PHASE THREE

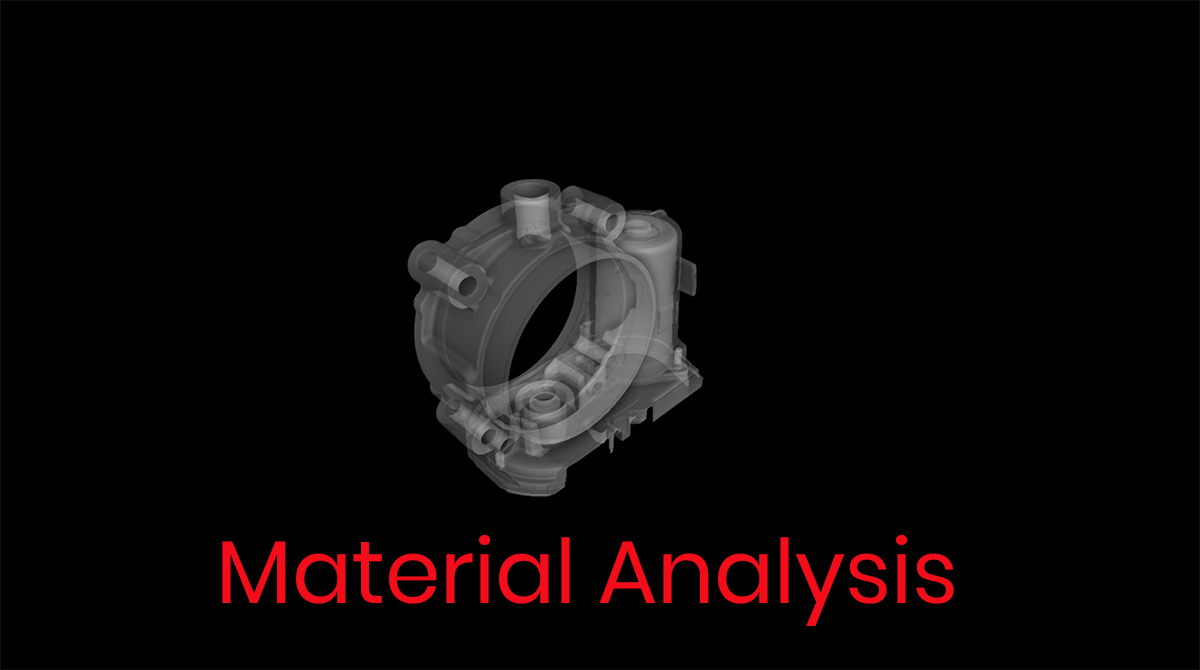

ANALYSIS

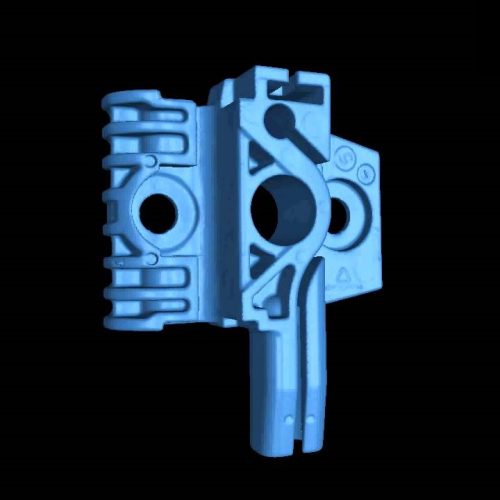

Depending on the Industrial X-Ray CT project, we analyze the reconstructed (3D imaging) results for either material or geometry based output requirements.

Material reporting is based upon internal density variations or percent volume changes. These types of Industrial X-Ray CT analysis include :

Visualizing virtual cross-sectional slices

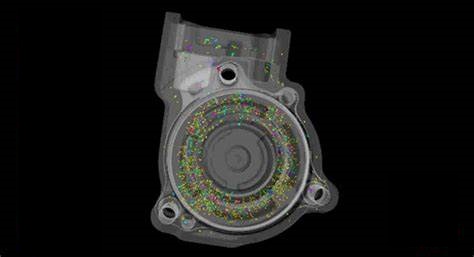

Porosity / Inclusion Analysis (Color coded voids, inclusions, and micro pores by volumetric size or percentage)

Enhanced Porosity (Automotive Industry Specific, P201 – 50097, P202 – 50098, P203 Analysis)

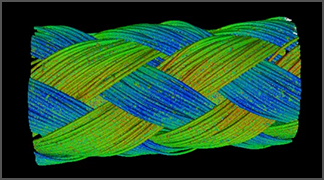

Fiber Analysis (Color coded fiber directional reporting)

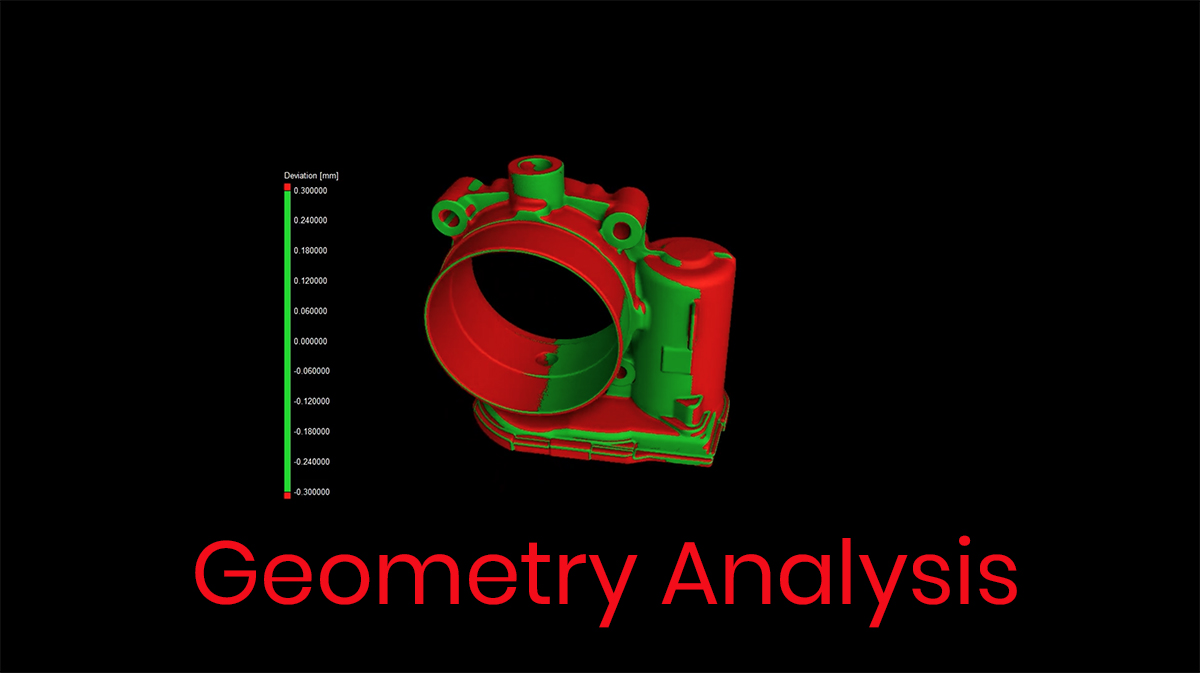

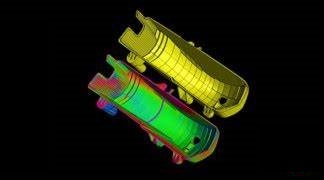

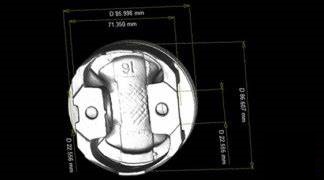

Geometry reporting is based upon measurement variations or dimensioning requirements. These types of Industrial X-Ray CT analysis include :

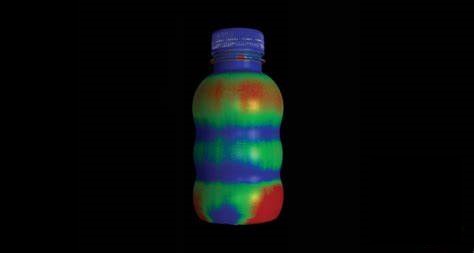

Part to CAD / Part Comparison (Color coded variations from nominal or another identical part. Alignment by: RPS, 3-2-1 alignment, best fit, sequential)

Wall Thickness Analysis (Color-coded results identifying insufficient or excessive wall thicknes)

First Article Inspection (Tolerancing based upon part print dimensions)

Enhanced FAI (AS9102 Form 3 Reporting)

Reverse Engineering (Generation of a STL file with internal & external part geometry)

PHASE FOUR

REVIEW

As all Industrial X-Ray CT projects are unique, each project is finalized between our lab and the customers key decision makers over a results web conference. If required, output deliverables can vary between picture files, excel files, presentations, 3D imaging / CT dataset viewing software, or in some cases STL files.

Need more info on Industrial X-ray?

Review our knowledge section below.

( CLICK SECTION AREAS TO EXPAND )

X-Ray (General Overview)

X-ray Overview

A form of electromagnetic radiation is referred to as X-radiation (X-ray). X-ray is known to be introduced by Wilhelm Rontgen, who named it X-radiation signifying the “unknown” or “unfamiliar” type of radiation. Very soon after the discovery, X-rays were being utilized for medical purposes. With today’s technological advancements, x-ray technology has many different uses ranging from diagnosing diseases to industrial part inspections.

What is a X-ray?

X-ray is a form of electromagnetic radiation with wavelengths shorter that UV rays, although longer than gamma rays. Electromagnetic radiation is radiant energy which is released, transmitted in waves or particles at altering frequencies and wavelengths. Since X-rays carry high levels of energy, it is classified as ionizing radiation, which can be harmful if high radiation dose is exposed to the human body. X-rays are classified in two different ways:

Soft X-rays: Relatively lower energy x-rays; anything below 5 KeV would be considered a soft x-ray. Soft x-rays can be absorbed in the air.

Hard X-rays: Relatively higher energy; anything above 5 keV would be considered a hard x-ray. Hard x-rays have the ability and energy to penetrate through different types of materials, hence, they are commonly used for industrial purposes to find internal defects in objects or parts.

How X-rays work

There are many different types of X-ray methods for medical and industrial use including radiographs, computed tomography (CT), fluoroscopy and real time x-ray. Each method has slight differences, although some factors are common: There is a detector to capture the x-ray images as well as an x-ray source with energy range depending on the purpose of the x-ray. To develop an x-ray, an x-ray source produces a beam of high energy electrons onto a metal film. The beam travels through space until it reaches the subject being x-rayed. The resulting X-ray image will be able to show internal aspects of the subject.

For example – in regards to Computed Tomography (CT) for industrial uses, there is a detector panel, x-ray source and a rotary table. To capture X-rays, the x-ray source shoots through the part and the detector panel captures the X-rays, which are reconstructed into a 3D model.

Uses of X-rays

With the development of X-ray technology over the years, the use of x-rays have become extremely diverse. From merely medical use, x-ray technology has been able to provide additional value for industrial purposes as well. The following briefly describes the use of X-rays for medical and use of x-ray for industrial aspects, with more emphasis on industry perspective.

- Industrial Uses:

- Industrial Computed Tomography

- Failure investigation – internal cracks/defect

- Comparison analysis for consistency

- Airport inspection/border control for truck inspection

- Industrial Radiography

- Approve/reject production parts

- Medical Uses:

- Patient diagnosis

- Cancer treatment

- Detect disease

Applications of X-ray

X-ray technology has two primary application:Medical applications and Industrial applications. For the purpose of this document, focus will be on Industrial X-ray applications. For industry perspective, X-rays are an invaluable source for nondestructive testing applications. X-rays fall under the category of Radiographic Testing (RT) as mentioned by American Society of Nondestructive Testing (ASNT). This non-destructive testing method provides an outlet for internal part analysis in 2D or 3D by utilizing x-ray technology. X-rays are a very common application of RT for accessing internal part analysis in 2D, for identifying failures or foreign material within a part.

Benefits of X-Rays

X-ray technology is a non-contact, non-intrusive and non-destructive technology, whether being applied for the medical industry or for industrial use. Although x-ray exposure can be harmful, the benefits of X-ray outweigh the risks if safety procedures are implemented properly. For industrial use, x-ray can be beneficial in the following ways:

- Non-destructive

- Internal part analysis

- Quick and feasible

- Ability to inspect part of various sizes and materials

- Allows users to detect failures pre-production

- Allows users to confirm part credibility and authenticity

Radiography (General Overview)

Radiography Overview

Radiography is very common method of inspection utilized for medical and industrial purposes. With technological advancements over the years, different methods of inspection have been introduced and have been classified as radiographic testing, in addition to X-ray. Commonly used to inspect and analyze industrial parts, users are now able to access radiographic testing NDT labs for extensive and accurate part data.

What is Radiography?

Radiography is a method of imaging which uses electromagnetic radiation, usually x-rays, to access internal aspects of a test subject. Radiography is often utilized to analyze the human body, although it is accessible to evaluate industrial parts. Radiography uses the science and theory of radiation to produce images for internal observation. According to Merriam-Webster dictionary, radiography is the process by which radiographs are made (different methods of doing so include X-ray, Computed Tomography, and Ultrasound etc.).

Difference between X-rays and Radiography

X-rays and radiography are often miscommunicated and implied as interchangeable terms. However, X-rays and radiography are not the same in theory or application. X-rays are considered one of the methods undertaken by Radiographic Testing (RT). Although x-rays are a form of radiography, they are not the only method of radiography. Radiography covers a wide range of different types of applications and test methods including Computed Tomography (CT).

Often, X-ray is the term used to describe the resulting image. However, the resulting image is referred to as a “radiograph”, whereas, the process of attaining that radiograph could possibly be X-ray. When x-rays were first discovered, it was an interchangeable term with radiography, as it was the sole method of radiographic testing. Now that multiple different methods are considered radiographic testing, the term “X-ray” can no longer be substituted for radiography.

How Radiography Works

Applications of radiography include medical and industrial radiography. For the purpose of this document, focus will be on industrial radiography. Industrial radiography involves exposing a test subject to powerful radiation which penetrates though the subject and reaches a documenting medium. This medium could possibly be an industrial X-ray film or a digital detector.

Low density materials such as aluminum are usually tested with radiography methods, which are based on electrically generated x-rays. Thicker materials with higher density such as steel are commonly tested with radiography methods, which are based on gamma radiation. The resulting image with any x-ray technology is reviewed in gray-scale format. Lower density areas, including areas with defects such as porosity or cracks for example, will appear dark on the resulting image, as more radiation passes through the object, and is captured by the detector panel. Areas with high density material will absorb the radiation and the resulting image will appear, as less radiation will be captured by the detector panel.

Applications of Radiography

Although there are different types of medical and industrial applications, for the purpose of this document, industrial applications will be examined further. There are many different types of industrial application with radiographic testing. All methods of radiographic testing can be utilized for failure investigation applications, analyzing part design and features or simply to inspect internal part structure. These radiographic techniques include the following:

- Film Radiography

- Computed Radiography

- Digital Radiography

When is Radiography necessary?

When a user has a need to investigate internal structure or features of a subject, radiography can be utilized. For industrial purposes, radiography can be utilized during the following stages of a parts life cycle:

- Design and feasibility test

- Prototype verification

- Pre-production inspection

- Production testing

- Pre-service/in-service inspection

- Part sorting

- Failure investigation

- Reverse engineering

Benefits of Radiography

Radiography testing provides many benefits to its users in both medical and industrial applications. Listed below are a few direct benefits of radiography for industrial applications:

- Non-destructive method of inspection

- Cut costs and time relative to other testing methods

- Research & Development guidance and insight

- Full failure investigation

- Part confirmation and verification

- Detect internal flaws and foreign material

Uses of Radiography

Uses of radiography for medical applications cover a broad range of studies that require the visualization of internal parts of the human body, using x-ray based techniques. For industrial applications, radiography can be used in many different ways for different industries:

- Aerospace – Ex. find fatigue in Castings

- Automotive – Ex. Find flaws such as porosity in Piston Head

- Medical Device – Ex. Locate foreign material in medical devices such as an insulin pen

- Packaging – Ex. Find leakage issues in packaged goods

- Consumer Products – Ex. Evaluate wall thickness of a bottled part

- Military & Defense – Ex. Confirm geometry and develop FAI reports for ballistics

History of Radiography & Role of Radiographers

In 1895, Professor Wilhelm Rontgen discovered the X-ray. Signifying the “X” with an unknown form of radiation, x-rays became a popular method of inspecting the human body. Radiographs at that time were known as Roentgenograms, and radiographers referred to as Skiagrapher (Ancient Greek for Shadow). Over the years, and with the addition and advancements of new technology classified under radiography, radiographers are also equipped to perform computed tomography, mammography, ultra sound, computed radiography etc.

In order to be qualified to perform such radiographic tests for industrial applications, the American Society of Nondestructive Testing have highlighted standards, examinations and experience required. Classified as NDT level 1, NDT level 2 and finally NDT level 3 with highest authority and qualifications credit to NDT level 3, radiographers must partake in personal certification or employer based certification to perform NDT.

Radiography (General Overview Continued - Industrial)

What is Industrial Radiography?

Industrial radiography is a form of nondestructive testing of products, utilizing different techniques, on the foundation of x-ray technology. X-ray and radiography are similar in the sense that “x-ray” is a technique used to develop a “radiograph.” However, commonly these terms are mistakenly used interchangeably.

Furthermore, industrial radiography (link to new radiography page) is concerned with industrial applications only, whereas x-ray could cover a broad range, including medical applications. Industrial radiography uses ionizing electromagnetic radiation in order to observe, evaluate and analyze the subject being tested. Industrial radiography is primarily concerned with the inspection of parts and structures nondestructively, by utilization radiation.

Equipment Required for Radiography

There are many different tools that are required dependent on the approach of the industrial radiography and x-ray radiography process. Some common tools for conducting industrial radiography and x-ray testing include:

X-ray or Gamma-ray source – whether it is an x-ray generator or gamma ray source via radioactive materials, a source is the most necessary aspect of industrial radiography. Depending on the project requirements, an industrial radiography or x-ray testing approach can be utilized. If the part is relatively large, requires high amount of radiation exposure in order to penetrate through the material, gamma-ray sources would be more applicable. With smaller part components ranging from plastics to metals, x-ray sources would be applied with techniques such as computed tomography (CT).

Recording medium – on the opposite side of the test subject needs to be a recording medium in order to capture the radiation and develop results for further analysis. Whether a film sheet is required or a digital detector panel, the images retrieved can be used to detect defects and failures. Although fil radiography is not obsolete for industrial applications, it is steadily being replaced by computed tomography (CT) and digital radiography (DR).

Processing Equipment – If the technique of analyzing part is film radiography, processing equipment such as chemicals are necessary to develop the image. For digital radiography or computed tomography, processing equipment such as computers and specialized software is necessary to develop, restructure and analyze the resulting image.

Testing

Industrial Radiography and X-Ray Testing Overview

Over the years, x-ray technology and nondestructive testing methods have advanced, in order to accommodate the growing needs of the industry. With different types of radiographic techniques and x-ray inspection, users are able to access full part data for different applications. Commonly, users outsource nondestructive testing projects for more accurate part results.

What is Industrial Radiography and X-Ray Testing?

Industrial radiography is a form of nondestructive testing of products, utilizing different techniques, on the foundation of x-ray technology. X-ray and radiography are similar in the sense that “x-ray” is a technique used to develop a “radiograph.” However, commonly these terms are mistakenly used interchangeably.

Furthermore, industrial radiography is concerned with industrial applications only, whereas x-ray could cover a broad range, including medical applications. Industrial radiography uses ionizing electromagnetic radiation in order to observe, evaluate and analyze the subject being tested. Industrial radiography is primarily concerned with the inspection of parts and structures nondestructively, by utilization radiation.

Types of Industrial Radiography

There are multiple different types of industrial radiography procedures. A brief overview of these procedures are explained below:

X-ray – This form of industrial radiography is produced by an x-ray generator. X-ray technology relies on electricity to be powered and utilized. When an electron is accelerated and comes in contact with other atomic particles, it forcibly decelerates, producing an x-ray. There are two different atomic processes:

Bremsstahlung radiation – When an electron accelerates because of an electric field of another charged particle, radiation is exerted, called Bremsstahlung radiation

K-sell/characteristic emission – when outer-shell electrons fill a void within inner shell of atom, radiation is exerted, characteristic to element.

Gamma-radiation (Gamma-rays) – This form of industrial radiography is produced from radioactive material (commonly mad-made) within the inspection system. The most common gamma-ray sources for industrial applications tend to be Iridium-192 and Cobalt 60. Gamma-rays do not need to rely on electricity to function, as they never turn off. They must be properly shielded when they are not in use. Gamma-rays have higher exposure of radiation, with the ability to inspect dense objects such as large pipelines.

Neutron Radiography (NR) – Although very rarely utilized, neutron radiography can be used for industrial applications. Neutrons have the ability to pass through very high density material, however, they have trouble inspecting low dense materials such as plastic. Since the amount of radiation is measurable (released from the opposite side of test subject), variying radiation can assist in identifying thickness of part.

Industrial Radiography Techniques

According to the American Society of Non-destructive Testing (ASNT), there are three distinct techniques in regards to industrial radiography:

Film radiography – Use of a conventional x-ray film, held in an envelope which allows x-rays to pass through. The resulting images are processed using special chemicals. This process is referred to as the “wet-process”.

Computed radiography – A mix of film radiography and digital radiography. Instead of a conventional x-ray film, a reusable photo-stimulated phosphor (PSP) plate is held in an envelope. To process the captured images, the envelope is transferred to a laser reader which develops a digital image.

Digital radiography – The radiation that crosses the subject being tested is captured digitally and can be translated into a computer immediately.

Non-destructive X-Ray Testing Inspection and Industrial Radiography

Industrial Radiography & x-ray testing has become invaluable for the testing, qualifications and verification of part components in the manufacturing cycle. Industrial radiography & industrial x-ray testing have revolutionized NDT methods of inspection by assisting in the following areas:

- Ensures safety and reliability of part

- Identify, locate and measure defects

- Density variations can be analyzed for structural evaluation

- Options of different approached for industrial radiography

- Quick, cost effective and accurate

- Ability to use part after testing and analysis

- Qualify and approve part components

Equipment Required for Radiography

There are many different tools that are required dependent on the approach of the industrial radiography and x-ray radiography process. Some common tools for conducting industrial radiography and x-ray testing include:

X-ray or Gamma-ray source – whether it is an x-ray generator or gamma ray source via radioactive materials, a source is the most necessary aspect of industrial radiography. Depending on the project requirements, an industrial radiography or x-ray testing approach can be utilized. If the part is relatively large, requires high amount of radiation exposure in order to penetrate through the material, gamma-ray sources would be more applicable. With smaller part components ranging from plastics to metals, x-ray sources would be applied with techniques such as computed tomography (CT).

Recording medium – on the opposite side of the test subject needs to be a recording medium in order to capture the radiation and develop results for further analysis. Whether a film sheet is required or a digital detector panel, the images retrieved can be used to detect defects and failures. Although fil radiography is not obsolete for industrial applications, it is steadily being replaced by computed tomography (CT) and digital radiography (DR).

Processing Equipment – If the technique of analyzing part is film radiography, processing equipment such as chemicals are necessary to develop the image. For digital radiography or computed tomography, processing equipment such as computers and specialized software is necessary to develop, restructure and analyze the resulting image.

Quality of Industrial Radiography

The quality of the x-ray testing method or industrial radiography approach is dependent on many different factors:

Size/ thickness of material – if the size and thickness of the material is too large for radiation to penetrate through, it will not be able to detect any flaws or defects, or even capture the structural complexity of a part. If the part is too small or consists of low density material and the radiation exposure is too high, the resulting image may produce scatter.

Material – The more dense the material is, the more radiation it tends to absorb. When there are defects within a material such as cracks or voids, more radiation passes through them, which the detector captures and processes in the final resulting image. Since the cracks or voids do not absorb any radiation, they will appear with a higher density on the resulting image – darker on the greyscale value. The areas with high dense material will absorb radiation, therefore, it will appear lighter on the greyscale, when analyzing the resulting image. The radiation source has to be set up so that it is not too high or low for a particular material being scanned. High radiation exposure for low dense materials will develop a scattered image. Low radiation exposure for relatively high dense materials will not provide the details a project may require in a resulting image.

Orientation – Depending on the area that needs to be inspected for industrial applications, the orientation of the part in accordance with the x-ray or gamma source plays a big role. The orientation of the part in regards to the x-ray source is determined on the basis of the purpose of the test (to identify failures/defect/wall thickness etc.)

Contrast/sharpness/graininess – A minimum contrast is required in order to retrieve high quality images to analyze failures, such as porosity. Image contrast is the density variations between an area and the background density on the radiograph – if the contrast is clear, it will aid in realizing failures more accurately. Similarly, sharpness of the imaging results can help look into detail of the part deviations from initial design and certain defects. The graininess of an image can also determine whether the results are of quality. Aspects like the orientation, and radiation exposure may need to be adjusted in order to access better quality images.

Applications of Industrial Radiography and X-Ray Testing

Industrial radiography and x-ray testing is one of the most common non-destructive testing methods within the industrial sector. From having the ability to inspect, quantify and qualify failures and defects to being able to access internal and external geometry, industrial radiography has become an indispensable tool for the industry. Applications vary depending on the type of material, size of part and inspection requirements, although industrial radiography and x-ray inspection are commonly used for testing welds, pipe, pipeline, concrete, machined parts, and metal components, solid and flat materials. This method of inspection is also regularly utilized by the following industries:

- Aerospace – ex. Castings

- Medical Devices – ex. Stints

- Automotive – ex. Piston head

- Military & Defense – ex. Ballistics

- Manufacturing – ex. Pre-production qualification of part

- Packaging – ex. Structural integrity/leak or failure analysis or package

Industrial Radiography – Safety

Since industrial radiography and x-ray testing expose high doses of radiation, certain standards and requirements are put into place in regard to the safe use and application of such a technology. Individuals who are looking to use radiography equipment for industrial applications must have a permit, license and training. In order to use industrial radiography or x-ray testing equipment, one must ensure all areas are free of people, who could possibly be adversely affected by the radiation exposure. Commonly, such tests and inspections are conducted after hours, to remove any risk of radiation exposure. Furthermore, different pieces of safety equipment must be utilized to ensure safety:

- Radiation survey meter: measures speed at which radiation is picked up

- Alarming dosimeter: alarms when radiographer is exposed to too much radiation

- Gas charged dosimeter: total radiation received, which can also be reset

- Thermoluminescent dosimeter (TLD): measures radiographers total exposure over time

Alternative Technologies

Although industrial radiography and x-ray testing are the most common method of Non-destructive testing method, many other methods can be utilized to analyze a part:

- Magnetic particle testing

- Liquid penetrant testing

- Ultrasonic testing

- Electromagnetic testing

- Visual testing

- Acoustic emission testing

- Guided wave testing

- Laser testing methods

- Leak testing

- Magnetic flux leakage

- Thermal/infrared testing

- Vibration analysis

Industrial Radiography & X-ray Testing Certification

Governed by the Nuclear Regulatory Commission (NRC), certain standards have been put into place in order to operate radiographic testing equipment. Certain safety courses have to be taken, with a completion of a number of on the job training hours and a complete written exam. A form of certification authorized by ASNT classifies three different levels of certification to be qualified for the operation of such equipment:

Level 1 – Individuals certified with level 1 are restricted to perform only certain calibrations or tests under supervisions by a higher level individual. They are able to report results, and are expected to follow instructions regarding procedure.

Level 2 – Individuals certified with level 2 are open to set up and calibrate inspection equipment, perform inspection according to standards and codes. These individuals are able to provide instruction to level 1 technicians, as well as report, interpret and evaluate results. Have knowledge of standards and codes.

Level 3 – Individuals certified with level 3 are specialized, experienced and qualified engineers or technicians. These technicians are able to direct NDT labs, and have extensive knowledge about testing, service and manufacturing processes as well as codes and standards.

Digital Testing

Digital Radiography (DR) Overview

Radiographic testing is a very common form of inspection for industrial applications, across all industries. Over the years, traditional x-ray processes have become obsolete and are being replaced with advanced radiographic testing techniques for the digital age. Digital radiography is a sustainable method of testing, which meets growing industry needs. Users often seek nondestructive testing labs for all digital radiography testing projects for accurate and quick results.

What is Digital Radiography?

Digital radiography (digital x-ray) is a form of x-ray imaging, where screen films and photographic films are replaced with a digitized detector. According to the American Society of Nondestructive Testing (ASNT), digital radiography digitizes the radiation that passes through an object directly on to a computer for review and analysis.

How does Digital Radiography Differ From Other Radiographic Testing?

There are three distinct types of radiographic testing techniques:

- Film radiography

- Computed radiography (CR)

- Digital radiography (DR)

Digital radiography differs from the remaining three techniques because it provides immediate imaging results available for inspection and analysis. With film radiography, there is use of films which require time for processing and inspection. Computed radiography uses a combination of film and digital radiography. Although it uses film cassettes to capture the resulting image, they are processed using a laser reader, which translates data into a digital image. Computed Tomography uses a digital detector to capture images, however, these are reconstructed into a 3D model, requiring more time for an incomparable resulting image in 3D. Depending on the purpose of the testing project, one of the four different radiographic testing techniques can be beneficial for internal part analysis.

How Digital Radiography Works

In order for digital radiography to work, two factors play a significant role:

- X-ray source

- Detector panel

A part is placed in the middle of an x-ray source and detector panel. The radiation released from the x-ray source shoots through the part and remaining radiation is captured by the detector panel. 2D x-ray images that are captured with the detector panel are immediately available to view on a computer. The higher the density of the part, the more radiation it will absorb. Since defective areas within a part (such as cracks or voids) consist of no density, radiation will pass right through and be captured with the detector panel. The resulting image will be in grayscale value. All defects such as porosity will be shown in darker scale value – black – whereas all areas with varying densities will be shown in varying lighter scale value – white.

Uses of Digital Radiography

The uses of digital radiography vary according to the project requirements. Since this is a non-destructive testing method, it becomes very useful across all stages of a parts life cycle. The most common uses for digital x-ray include:

- Pre-production evaluation and validation of part

- Ensures safety and reliability of part

- Failure investigation tool

- Identify, locate and measure defects

- Production lot inspection

- Density variations can be analyzed for structural evaluation

- Quality control management tool

- Quick, cost effective and accurate

- Part approval/rejection tool

- Ability to use part after testing and analysis+

- Qualify and approve part components

Applications of Digital Radiography

For industrial applications, radiography can be used in many different ways for different industries. This x-ray technology reduces costs and minimizes time for reviewing and analyzing parts. Applications vary by industry, some of which may include:

- Packaging – Ex. Find leakage issues in packaged goods

- Aerospace – Ex. find fatigue in Castings

- Military & Defense – Ex. Confirm geometry and develop FAI reports for ballistics

- Medical Device – Ex. Locate foreign material in medical devices such as an insulin pen

- Automotive – Ex. Find flaws such as porosity in Piston Head

- Consumer Products – Ex. Evaluate wall thickness of a bottled part

Benefits of Digital Radiography

Digital radiography testing provides many benefits to its users for industrial applications. Listed below are a few direct benefits of digital x-ray for industrial applications:

- Non-destructive method of inspection

- Cut costs and time relative to other testing methods

- Research & Development guidance and insight

- Full failure investigation

- Part confirmation and verification

- Detect internal flaws and foreign material

History of Digital Radiography

In 1895, Wilhelm Rontgen discovered x-rays while experimenting. The “x” is to signify the unknown form of radiation. Rontgen figured this would change once there was further understanding of radiation. Shortly after the discovery, x-rays were used for medical applications to diagnose and analyze the human body. Industrial applications were the next use for x-rays, inspecting and analyze aerospace components. With growing industry needs, technologically advanced forms of x-rays were introduced, which were classified under radiographic testing techniques. Today, users are able to utilize different radiographic testing techniques to inspect anything from medical devices to military equipment.

Real Time X-Ray

Real Time X-Ray Overview

Real time x-ray is referred to as the inspection of a test subject using x-ray technology, while the subject is in motion. Since this concept is relatively new in the industry, users often outsource such real time x-ray projects to specialized NDT labs.

What is Real Time X-Ray?

Real time x-ray is referred to as the concept of conducting x-ray testing on a test subject while it is in motion, in use or functioning. Real time x-ray has the ability to access internal and external data of structural composition of a test subject.

This testing process is commonly performed at offline inspection labs. Real time x-ray provides users with invaluable insight on part functionality, internal failures and part reliability.

How Does Real Time X-Ray Work?

In order to perform real time x-ray inspection, there are three key factors required:

- X-ray source

- Detector Panel (digitized detector/computerized detector)

- Software

The x-ray source penetrates through a part while the remaining radiation is captured by the detector panel. The detector panel captures several hundred to several thousand 2D X-ray images, while the part is functioning, in motion or in use (for a part that does not require any external support for in-use capability). The resulting images are converted into a video format using a specialized software. The video format reveals the internal and external features of the test subject, while it is in motion. All internal structures, fit and function, defects, discrepancies can be identified and located. The video can be further utilized by inspecting stills or conducting failure analysis.

Uses of Real Time X-Ray

There are several uses for this indispensable technology that allows users the ability to identify internal part features, including but not limited to:

- Failure investigation

- Research & Development

- Design feasibility study

- Qualification of part during pre-production

- Reliability assessment

- Process & quality control

- Comparison analysis – perfect vs. defective parts – functioning failures

Applications of Real Time X-Ray

Application for real time x-ray exists for all industries manufacturing parts which can be inspected while in motion without external support. These industries include:

- Aerospace

- Automotive

- Medical Device

- Packaging

- Consumer Products

- Military and defense

Benefits of Real Time X-Ray

Aside from being an easy way to inspect parts accurately, real time x-ray provides users with numerous benefits, including:

- Non-destructive testing method – the part being inspected is available for use after testing

- Part analysis for internal components

- See effect on part in motion with an easy to view video

- Identify cause of effect or failures

- Highlight internal discrepancies

- Confirm part use – comparison analysis

- See internal interaction of components