CT Services - Part Inspection Lab

We help companies thoroughly investigate

parts & assemblies with our high quality

CT services paired with

expert analytical support.

PHASE ONE

CONSULTATION

After the initial inquiry, our services begin by having an in-depth discussion with the inquiring individual and interested parties. If the fit is right for our CT services, the feasibility review considers part/assembly type, material, regions of interest, and the objective for the CT scan.

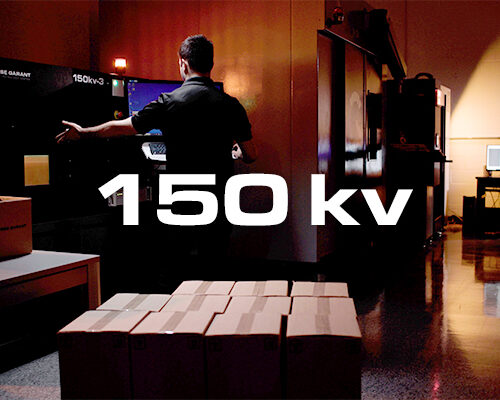

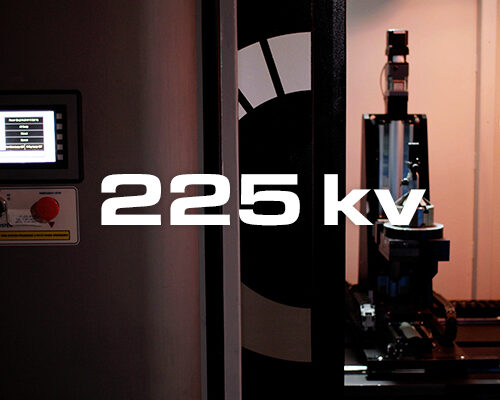

PHASE TWO

CT – SYSTEM MATCHING

We then match the NDT or Metrology inspection need with one of our many and highly diverse CT services imaging machines. Our industrial lab utilizes 100kv, 150kv, 225kv, 450kv, and 3MEV linear accelerator CT systems with LDA’s and flat panel detectors.

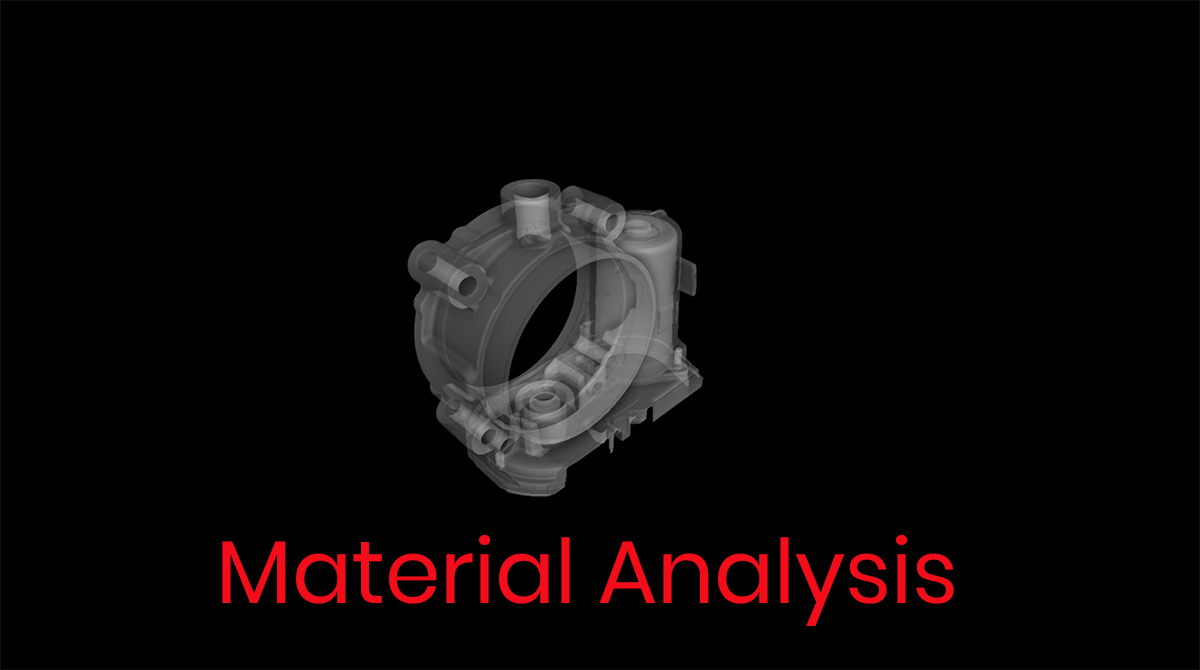

PHASE THREE

ANALYSIS

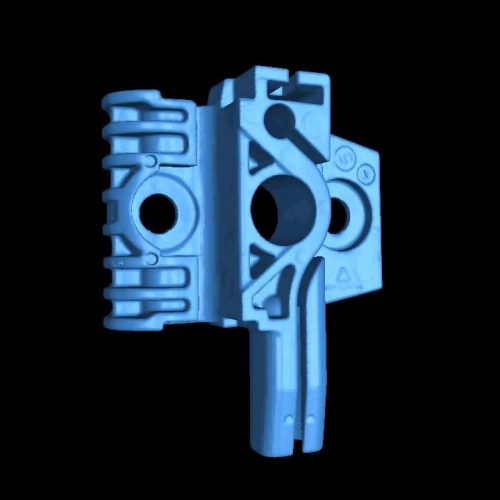

Depending on the CT project, we analyze the reconstructed (3D imaging) results for either material or geometry based output requirements.

Material reporting is based upon internal density variations or percent volume changes. These types of CT services analysis include :

Visualizing virtual cross-sectional slices

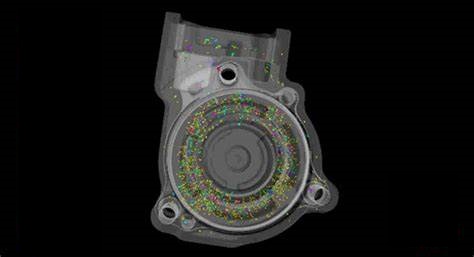

Porosity / Inclusion Analysis (Color coded voids, inclusions, and micro pores by volumetric size or percentage)

Enhanced Porosity (Automotive Industry Specific, P201 – 50097, P202 – 50098, P203 Analysis)

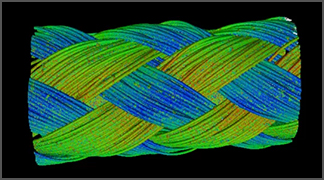

Fiber Analysis (Color coded fiber directional reporting)

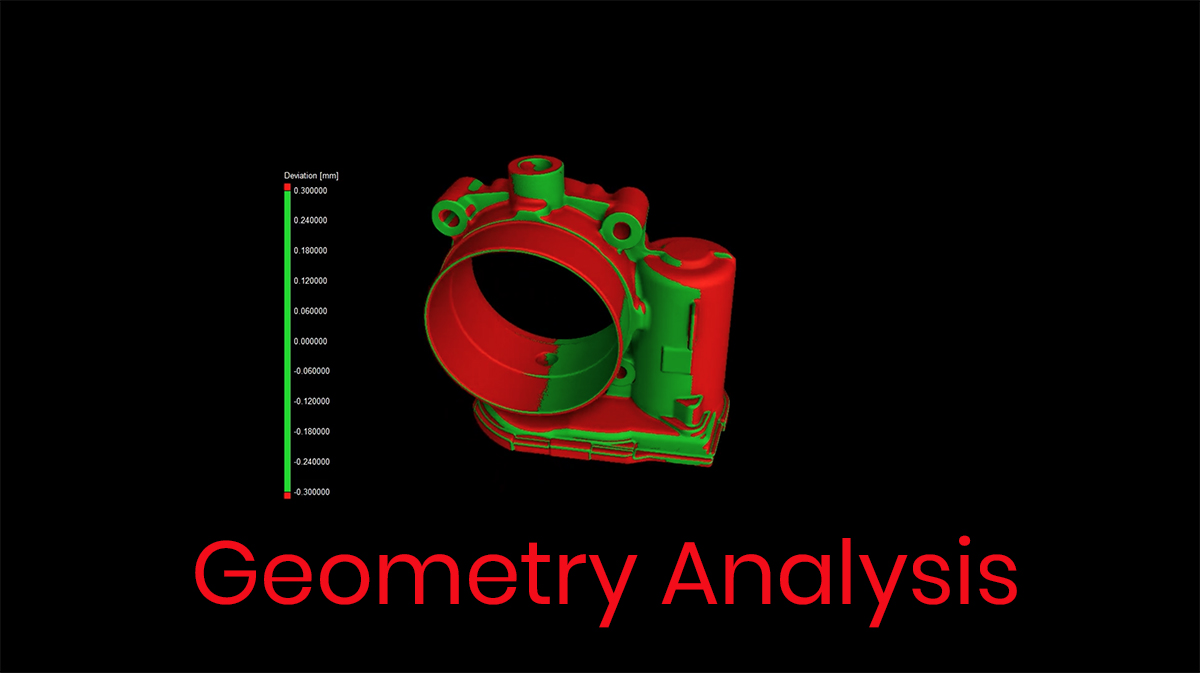

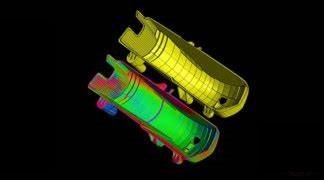

Geometry reporting is based upon measurement variations or dimensioning requirements. These types of CT services analysis include :

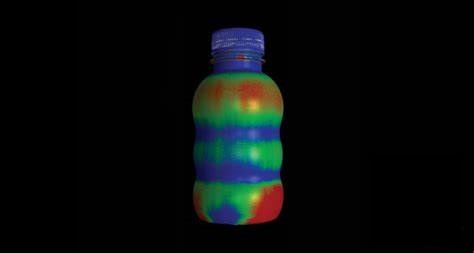

Part to CAD / Part Comparison (Color coded variations from nominal or another identical part. Alignment by: RPS, 3-2-1 alignment, best fit, sequential)

Wall Thickness Analysis (Color-coded results identifying insufficient or excessive wall thicknes)

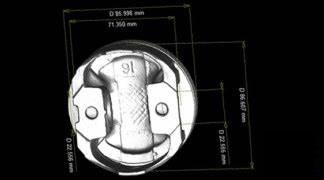

First Article Inspection (Tolerancing based upon part print dimensions)

Enhanced FAI (AS9102 Form 3 Reporting)

Reverse Engineering (Generation of a STL file with internal & external part geometry)

PHASE FOUR

REVIEW

As all CT service projects are unique, each project is finalized between our lab and the customers key decision makers over a results web conference. If required, output deliverables can vary between picture files, excel files, presentations, 3D imaging / CT dataset viewing software, or in some cases STL files.