Industrial CT Scanning - Services

Part Inspection Lab

We help companies thoroughly investigate

parts & assemblies with our high quality

Industrial CT Scanning services

paired with expert analytical support.

PHASE ONE

CONSULTATION

After the initial inquiry, our services begin by having an in-depth discussion with the inquiring individual and interested parties. If the fit is right for our industrial CT scanning services, the feasibility review considers part/assembly type, material, regions of interest, and the objective for the CT scan.

PHASE TWO

INDUSTRIAL CT SCANNING – SYSTEM MATCHING

We then match the NDT or Metrology inspection need with one of our many and highly diverse industrial CT scanning imaging machines. Our industrial lab utilizes 100kv, 150kv, 225kv, 450kv, and 3MEV linear accelerator CT systems with LDA’s and flat panel detectors.

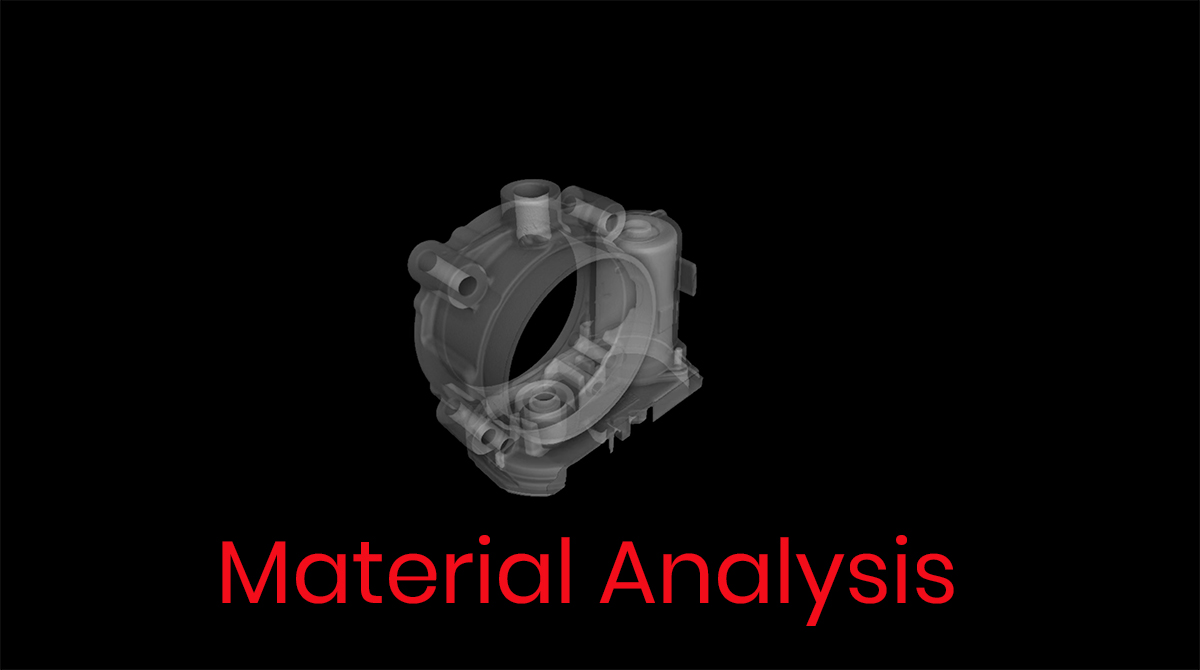

PHASE THREE

ANALYSIS

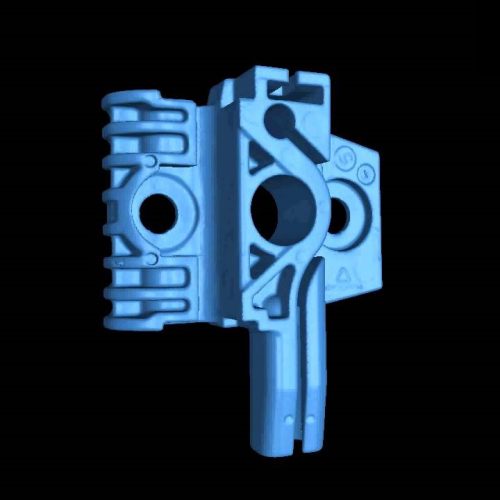

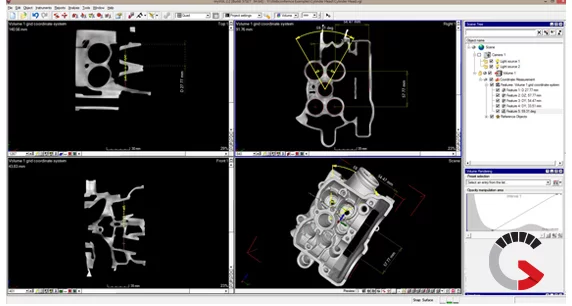

Depending on the Industrial CT Scanning project, we analyze the reconstructed (3D imaging) results for either material or geometry based output requirements.

Material reporting is based upon internal density variations or percent volume changes. These types of Industrial CT Scanning analysis include :

Visualizing virtual cross-sectional slices

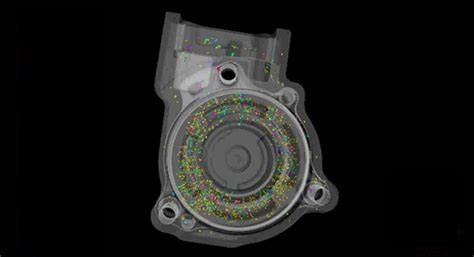

Porosity / Inclusion Analysis (Color coded voids, inclusions, and micro pores by volumetric size or percentage)

Enhanced Porosity (Automotive Industry Specific, P201 – 50097, P202 – 50098, P203 Analysis)

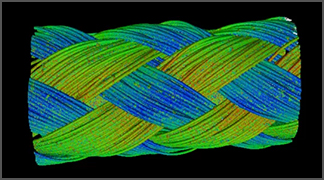

Fiber Analysis (Color coded fiber directional reporting)

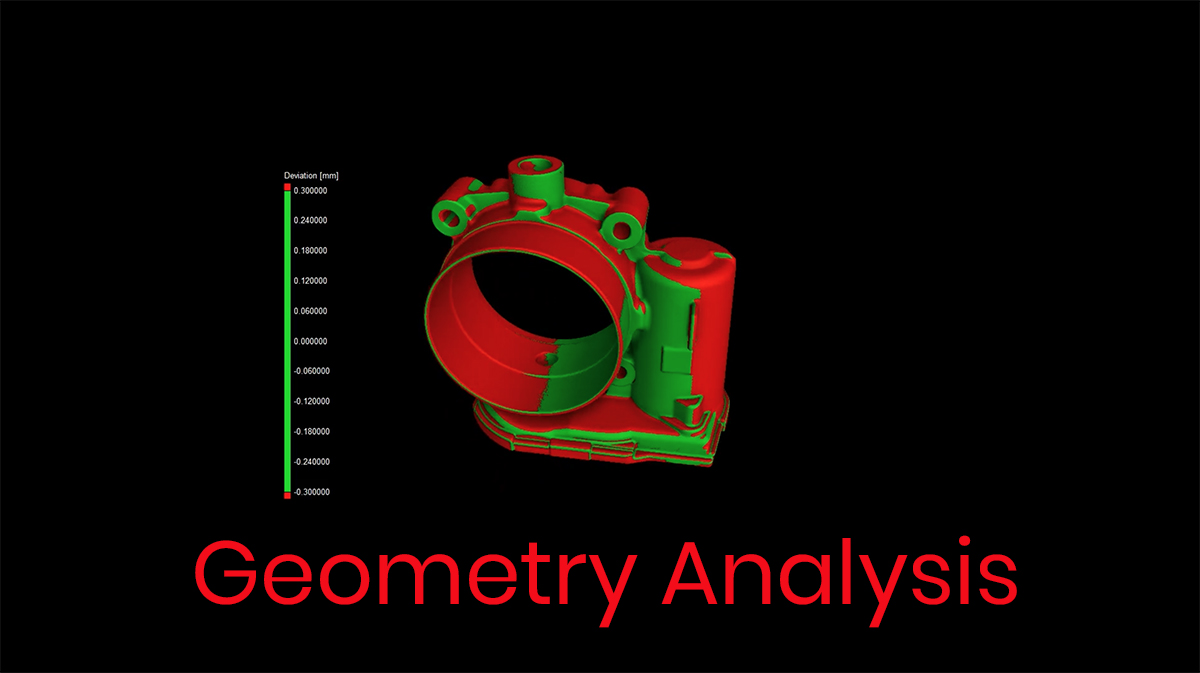

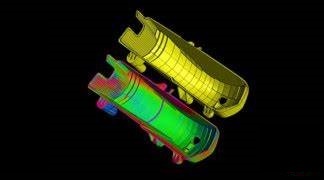

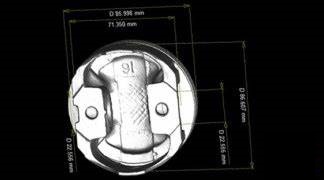

Geometry reporting is based upon measurement variations or dimensioning requirements. These types of Industrial CT Scanning analysis include :

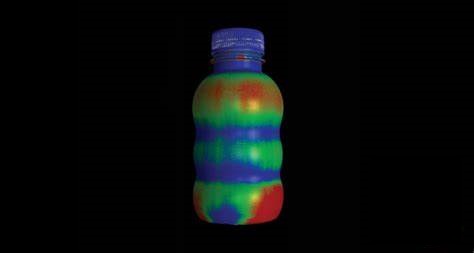

Part to CAD / Part Comparison (Color coded variations from nominal or another identical part. Alignment by: RPS, 3-2-1 alignment, best fit, sequential)

Wall Thickness Analysis (Color-coded results identifying insufficient or excessive wall thicknes)

First Article Inspection (Tolerancing based upon part print dimensions)

Enhanced FAI (AS9102 Form 3 Reporting)

Reverse Engineering (Generation of a STL file with internal & external part geometry)

PHASE FOUR

REVIEW

As all Industrial CT Scanning projects are unique, each project is finalized between our lab and the customers key decision makers over a results web conference. If required, output deliverables can vary between picture files, excel files, presentations, 3D imaging / CT dataset viewing software, or in some cases STL files.

Need more info on Industrial CT Scanning?

Review our knowledge section below.

( CLICK SECTION AREAS TO EXPAND )

What is Industrial CT Scanning

What is Industrial CT Scanning

Computed Tomography (CT) Scanning, also known as industrial CT scanning, is based on radiographic technology, which provides an ideal testing technique in order to locate and measure volumetric detail in three dimensions. The ability of x-ray to penetrate through varying densities allows CT inspection results to provide nondestructive physical characterization of internal features and structures of a part or component.

Industrial CT scanning is able to access internal data equally well on metallic and nonmetallic specimens, solid and fibrous materials, and smooth and irregularly surfaced objects.

When is Computed Tomography Necessary?

Computed tomography is necessary when a user is looking to evaluate, analyze or test the internal and/or external features of a component without destroying the object. Industrial Computed Tomography is generally necessary during five different manufacturing stages:

- Pre-production – design and analysis

- Production – evaluate consistency

- Failure investigation – locate defects

- Lot inspection – repeatability test

- Reverse engineering – design adjustment or research & development

Types of Equipment

Generally, there are two basic types of medical and Industrial CT Scanning systems. There are parallel x-ray beam scanners and fan x-ray beam scanners. Parallel x-ray beam scanners can be categorized into first and second generation systems, similarly fan x-ray beam systems are categorized into third and fourth generation systems. These different types of CT scanners have been named according to their method of data collection, as opposed to the shape or structure of the beam itself.

Most Common types of Equipment

Pencil Beam Systems—The x-ray beam is collimated to a pencil and the effective pixel size becomes the size of the beam on the detector area. The beam is translated over the object and the object rotated after each pass of the beam over the object or the beam and detector are translated and rotated around the object to build up linear slice profiles. If a three dimensional data set is desired the object or beam/detector must elevate so that multiple slices are generated. The advantage of this method is detector simplicity and scatter rejection with the primary disadvantage being long scan times.

Fan-Beam Systems—The x-ray beam is collimated to a fan and detected by a linear detector array that usually has a collimator aperture. The pixel size is defined by the width of the fan-beam on the detector height (vertically) and by the detector element pitch (horizontally). Linear profiles are captured as the object or beam/detector rotates. If 3D data is required, the object or beam/detector must elevate to capture multiple slices. The advantage of this method is faster scan times than pencil-beam systems and some scatter rejection with the primary disadvantage being long scan times for 3D data.

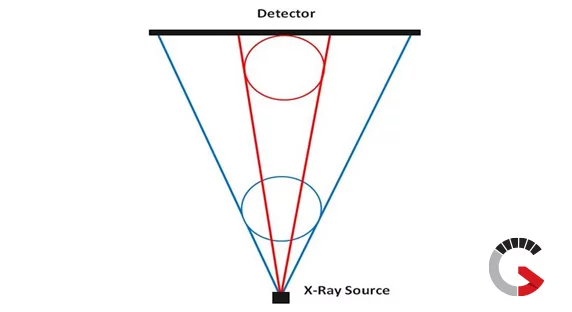

Cone-Beam Systems—The x-ray beam is usually collimated to the entire or a selected portion of the active area of a two dimensional detector array and full 2D images are captured as the object or beam/detector rotates. In this manner multiple slices are generated without needing to elevate. The primary advantage of this technique is speed or acquiring 3D data, with the primary disadvantage being increased scatter due to larger field of view.

Common Methods for Image Caputre

Translate-Rotate Motion—w detThe object or detector is translated in a direction perpendicular to the direction and parallel to the plane of the X-ray beam. Full data sets are obtained by rotating the object between translations by the fan angle of the beam and again translating the object until a minimum of 180° of data have been acquired. The advantage of this design is simplicity, good view-to-vieector matching, flexibility in the choice of scan parameters, and ability to accommodate a wide range of different object sizes, including objects too big to be subtended by the X-ray fan. The disadvantage is longer scan time. Reconstruction software must correctly account for fan/cone beam effects which can be complicated by translation of the object.

Rotate-Only Motion—The object remains stationary and the source and detector system is rotated around it or the object rotates and the source and detector remain stationary, it is the most common form of motion. A complete view is generally collected by the detector array during each sampling interval. A rotate-only scan has lower motion overhead than a translate-rotate scan, and is attractive for industrial applications where the object to be examined fits within the fan/cone beam, and scan speed is important. The sample translates and rotates, or both, or the source/detector system rotates, the principles of industrial CT scanning are the same. In 2D fan beam type systems, the sample/object may also be elevated through the fan beam in order to build up a three dimensional stack of cross-sectional views. In a cone beam type system, the rows of the detector array provide the third dimension. The sample/object may need to be elevated or translated in order to provide complete coverage if the object is larger than the cone beam (the projected area of the sample/object on the detector array area.)

Types of Xray sources for Industrial CT Scanning systems

Electrical X-ray generators offer a wider selection in peak energy and intensity and have the added safety feature of discontinued radiation production when switched off. Filtering of the x-ray beam can “Harden” the x-ray spectrum by reducing the amount of lower energies which can help reduce artifacts. Harder beam spectrum results in lower image contrast and may need for higher primary beam exposure dose, therefore, selection of the correct filtering is very important.

X-ray tubes and linear accelerators (linacs) are typically several orders of magnitude more intense than isotope sources. However, X-ray generators have the disadvantage that they are less stable than isotope sources. X-rays produced from electrical radiation generators have source spot sizes ranging from a few millimeters down to a few microns. Reducing the source spot size reduces geometric unsharpness, which enhances detail detection. However, the basic spatial resolution of the detector must also be able to support this increased spatial resolution. Smaller source spots permit higher spatial resolution but at the expense of reduced X-ray beam intensity. Reduced X-ray beam intensity implies longer scan times or inspection of smaller or less dense objects. Unlike radiography, an industrial computed tomography scanner can require extended, continuous usage of the X-ray generator so an increased cooling capacity of the X-ray source is required.

Isotope Sources—A Isotope source can have the advantages of small physical size, portability, low power requirements, simplicity, and stability of output. The disadvantages are limited intensity per unit area, limited peak energy, and increased regulatory/safety concerns.

Synchrotron Radiation (SR) Sources— Synchrotron radiation (SR) sources with special equipment produce very intense, naturally collimated, narrow bandwidth, tunable radiation. CT systems using SR sources can employ essentially monochromatic radiation. With present technology, however, practical SR energies are restricted to less than about 20 to 30 keV. Since any industrial CT scanning system is limited to the examination of samples with radio-opacities consistent with the penetrating power of the X rays or gamma rays employed, monochromatic SR systems can, in general, image only small low density objects.

The role of Spot Sizes—The source spot is the source region from which X rays or gamma rays emanate. In an electrical radiation generator, like an X-ray tube or linear accelerator, it is the area where the electrons strike the target. The size and shape of the source spot is an important determinant of the aperture function. For instance, source spots in linear accelerators are typically shaped as curved; whereas source spots in X-ray tubes are often double-peaked. Since source spots do not generally have sharp edges—or even symmetric shapes, it is common practice to define an effective size for convenience. The actual intensity distribution is important information, but is too complex to be readily useful. Consequently, reported source spot sizes are a function of the definition and method used to measure them. The average radius of the region from which 99 % of the emissions emerge will be much larger than the standard deviation of the intensity distribution. In other words, source spot characteristics can be quantified in different ways. For this reason, comparisons between sources, especially those provided by different suppliers, are difficult to make. Another source factor to consider is stability. In selecting an electrical source, appreciate that spot position can wander over time, and changes in accelerating potential can change the size as well.

Technology challenges with Industrial CT Scanning

A potential drawback with CT imaging is the possibility of artifacts in the data. An artifact is anything in the image that does not accurately reflect the true geometry in the part being inspected. Because they are not real, artifacts limit the user’s ability to quantitatively extract density, dimensional, or other data from the image. Therefore, as with any technique, the user must learn to recognize and be able to discount common artifacts. Some image artifacts can be reduced or eliminated with CT scanning by improved scanning practices, and others are inherent in the methodology. The reconstruction problem places a number of severe constraints on the data. Since the presence of random noise corrupts the information, one would expect the minimum sampling requirements to be greater than they are for noise-free data as well as to be sensitive to the algorithm employed

How Industrial CT Scanning Works

How Industrial CT Scanning Works

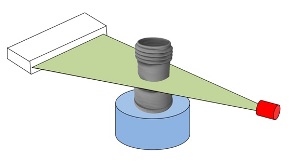

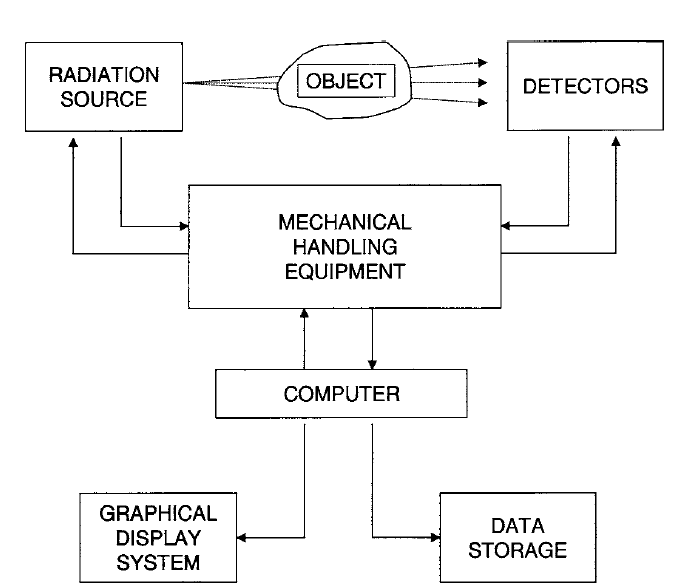

From being used for medical applications in the 1970’s, CT technology has transformed into a conventional method of testing and inspection for industrial applications. With the use of an X-ray source, detector panel and a rotary table, users are able to access accurate internal and external data set of a testing subject. As a part rotates 360 degrees on a rotary table, a pre-determined number of 2D x-ray cross sectional slices are captured, depending on the amount of data required.

When the first CT scanning instruments were introduced in the 1970’s for medical applications, finite-series expansion algorithms, algebraic reconstruction techniques and simultaneous iterative reconstruction techniques were utilized for reconstruction of the cross-sectional slices and data sets. These methods of reconstruction have become obsolete for commercialized industrial CT scanning instruments, due to their lack of speed. For use of industrial CT systems today, transform methods, a restorative algorithm (based on analytical inversion formulas) are implemented as they as much faster than traditional methods of reconstruction of CT data set. This method of reconstruction also allows for far greater image quality and accuracy.

Once the data set has been re-constructed into a 3D rendering, users are able to access internal and external part features including geometries, failures and explore the interaction of internal structures and assemblies.

How to conduct CT scans

In order to conduct a industrial ct scanning scan, a radiographer must be present to prepare the subject for scanning and calibrate the system in accordance to the purpose of the scan. Although there are many steps that are subject to the part being scanned, the following are common steps a radiographer takes to conduct a CT scan:

Match the part size and material to the appropriate x-ray source with high or low energy exposure depending on the purpose of the scan.

Place the part on the rotary table – located between the digital detector panel and x-ray radiation source. Ensure that the system has been closed shut before beginning CT scanning process.

Begin the radiation exposure process and select system settings based upon gained knoweldge. As the part rotates 360 degrees, the x-ray source penetrates through the part. The varying density of the part absorbs varying amounts of radiation. The remaining radiation travels to the detector panel, which captures a 2D x-ray image. This process is repeated to capture hundreds to thousands of 2D x-ray images.

Several hundred to thousand 2D x-ray images which are captured are reconstructed mathematically to develop a 3D rendering or a 3D model of the part being scanned. This model is used for further internal and external analysis of the part, whether it is to identify internal failures or to conduct a dimensional analysis.

Radiation Detection/Image Capture – Industrial CT Scanning Machine

The detection system converts the transmitted radiation into an electronic signal. The detector element is typically a scintillation detector that is optically coupled to a photo-conversion device such as a photodiode or photomultiplier tube. Alternatively, some systems use other types of detectors. For fan-beam type systems, the in-plane detector width is determined in part by the spatial resolution requirement.

This detector width is either designed in the system or, for variable aperture systems, can be set by some kind of shielding aperture plates that define the detector’s field of view. The detection system may consist of a single sensing element, an area array of sensing elements, or a linear array of sensing elements. The more detectors used, the faster the required scan data can be collected; but there are important trade-offs to be considered.

(1) A single detector provides the least efficient method of collecting data but entails minimal complexity, eliminates concerns of scatter between elements, differences in detector response, and allows an arbitrary degree of collimation and shielding. Translation motion is required for two dimensional reconstructions and elevate motion is required to create three dimensional reconstructions.

(2) An area detector provides the most efficient method of collecting data but entails the transfer and storage of large amounts of information, forces trade-offs between scatter, elements, and detector efficiency, and creates serious collimation and shielding challenges. However, using cone beam reconstruction algorithms three dimensional renderings of the object can be made.

(3) Linear arrays have performance characteristics intermediate between these two extremes, for example, reasonable scan times at moderate complexity, acceptable scatter between elements, and differences in detector response. Linear arrays have a flexible architecture that typically accommodates good collimation and shielding but require elevate motion for three dimensional reconstructions. In some cases, several linear areas are combined to allow faster scans while keeping some of the collimation benefits.

(4) An important aspect of the detection system is the electronics system used to convert the analog signal received to a digital stream for processing. The front-end analog electronics amplify the detector signal to a magnitude that can be digitized. Fast systems demand good fidelity of the amplified signal. What makes the task especially demanding is that many signals, differing by several orders of magnitude, are frequently multiplexed on the same line in rapid succession; intersignal amplification rates are measured in microseconds. The analog to digital (A/D) conversion is performed as close to the analog amplification chain as possible. The accuracy requirement of the A/D must be consistent with the statistical limitations of the largest and the smallest detectable signals.

Accuracy of Mechanical Handling Equipment Motion Control/Manipulation Systems

The object manipulation system has the function of holding the object and providing the necessary range of motion to position the object area of interest between the radiation source and detector. Since spatial resolution is limited by many things, including the relative position of the object with respect to the source and detector, any problems with alignment or accuracy of the mechanical system will show up as degraded resolution. It is typically more difficult to align hardware for translate-rotate motion machines, but the sampling rate is adjustable up to some limit. In contrast, rotate-only motion machines typically are not as difficult to align, but they do not give the option of adjusting linear sampling to satisfy the required sampling rates. In either case, artifacts occur and the resolution is degraded if alignment is compromised. (1) Because the inherent resolution of a system can be degraded by the mechanical handling equipment, fine spatial resolution requirements can drive mechanical designs and tolerances to extremely high costs. Typically, system designs can accommodate spatial resolutions up to some limit. Beyond that limit, redesign with different, more accurate system components and different assembly procedures is required.

Reference:

ASTM E1672-12, Standard Guide for Computed Tomography (CT) System Selection, ASTM International, West Conshohocken, PA, 2012, www.astm.org

Analyzing

The resulting scan is a set of voxel based data portraying the varying density of the part, in varying grayscale value. Density of a part absorbs the radiation which is exposed to the part being scanned. Since the cracks or voids do not absorb any radiation, they will appear with a higher density on the resulting image – darker on the greyscale value. The areas with high density material tend to absorb more radiation, thus, appearing lighter on the greyscale value. The images are analyzed similar to any x-ray or radiographic testing technique. For industrial CT scanning, a 3D model is reconstructed, which can be further analyzed for internal failures, measurements and wall thickness, to name a few. The results can be color coordinated according to project requirements to ease the visual of analysis.

Benefits of using Industrial CT Scanning

The main advantage for this technology is the fact that it provides highly accurate testing results without applying any pressure, stress or external forces on the subject being scanned. The following is a brief list of all the major benefits this technology offers:

- Nondestructive testing method

- Quantitative density evaluations

- Geometrical representations

- Cross sectional data and 3 dimensional data

- Images are easy to interpret than conventional radiographic data

- Quality control tool for failure investigation and preproduction inspection

- Internal and external part inspection

- Quick and accurate resulting data

- Accessible with the use of outsourced NDT labs

- Saves manufacturing cost (NDT)

- Cut costs and reduce time to production

- Accurate and precise means of measurement

- Access multiple different types of analysis with one CT dataset

- Non-invasive and non-intrusive method of inspection

- Research and development tool

- 3D internal visual and representation of part