Part to Part - CT Scanning Services

Part Inspection Lab

We help companies quickly identify part deviations between products using our Metrology based CT scanning services

Part to PART

Most of our clients identify internal imaging with a personal experience in the medical industry. However, contrary to popular belief our CT Scan services are found to be highly beneficial for inspection of industrial parts and assemblies.

Our advanced Industrial (Computed Tomography) CT Scanning services are able to aid manufacturers when inspecting difficult to measure part features with micro measurement variations from an identical or similar product.

PART TO PART

CT SCANNING SERVICES

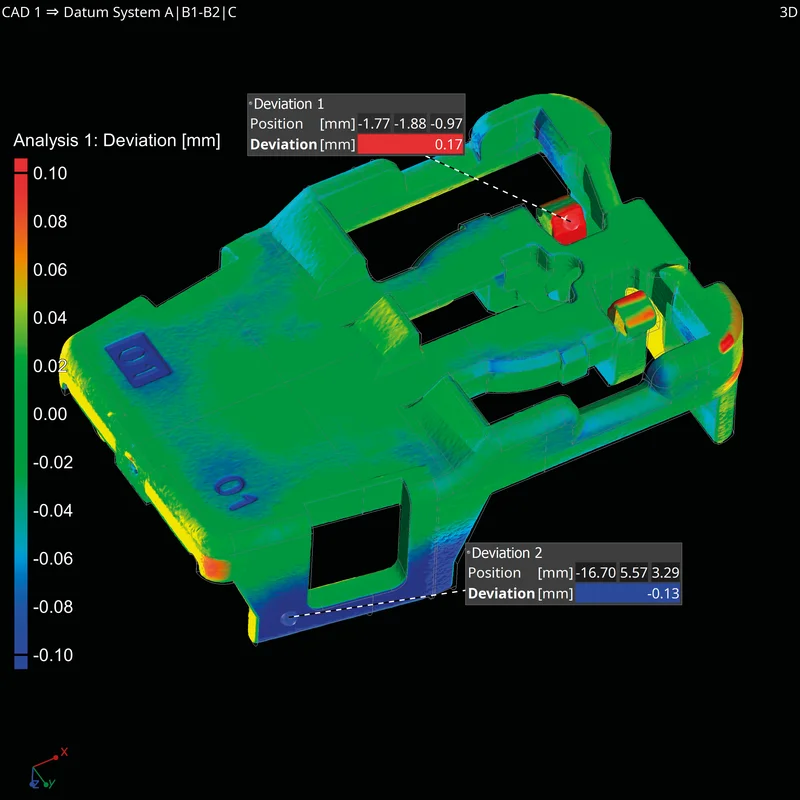

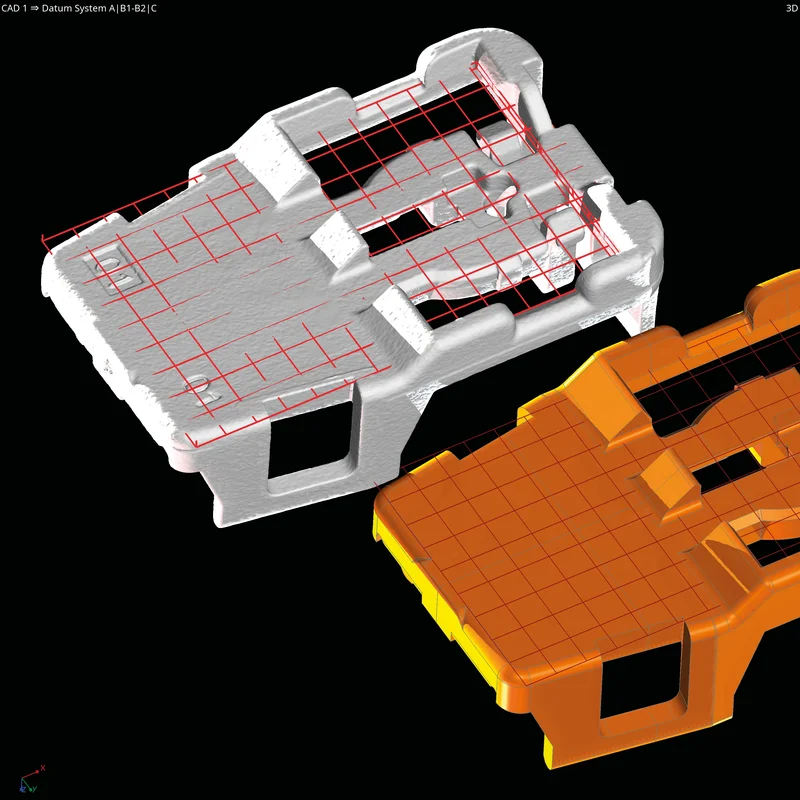

After two parts have been scanned, both datasets are compared together. Alignment is performed by either a best fit method or predetermined datum’s. Results are supplied in a color coded model showing deviations between each part for internal and external geometry.

In addition to the 3D color coded model, 2D cross sectional whisker plots are also included with the results to show deviations in cross sectional slices between both parts.

BENEFITS

- Results show differences between identical parts manufactured from different; locations, processes, or tool cavities.

- Results show internal and external differences between both scanned partsResults can show differences in 2D cross sectional slices and in 3D.

- Results can show differences in 2D cross sectional slices and in 3D.

Need more info on part to part comparisons?

Review our knowledge section below.

Alignment to a similar part is crucial for comparative measurement results. It enables the extraction and comparison of parts and measured dimensions and the investigation of assemblies.

With Volume Graphics software, you can:

- Align any data set to a reference data set using point-, surface-, and geometry-based approaches:

- Point-based: RPS and 3-2-1 alignment.

- Surface-based: Best fit, also with constraints or partial areas, as well as feature-based, focusing on characteristic areas.

- Geometry-based: Sequential alignment allows for the imitation of physical alignments, creating corresponding pairs of geometry one after another, decreasing more and more degrees of freedom. Remaining degrees can be fixed with a best fit for the whole or partial model.

- Tolerance alignment results to determine their quality.

- Use custom and local datum systems, providing automated measurement updates when changing alignments.

Get an easy-to-understand visualization of deviations of two or more scanned objects.

Part to part comparison features:

- Give you a color-coded comparison between voxel data (also referred to as false color plot).

- Allow you to position annotations individually, tolerate them, and place min./ max. information automatically.

- Statistically analyze a full part or rule-based created components.

- Have an adjustable color bar for smooth or stepped color transitions and transparent areas.

- Offer hairline rendering in 2D slices.