CT Scannng - Services by Material Type

We help companies internally inspect

their parts & assemblies manufactured

from a wide range of materials with our

CT scanning inspection services.

Supported Materials

How Material Effects Computed Tomography Results

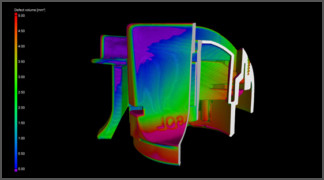

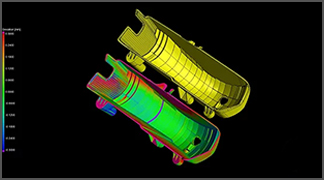

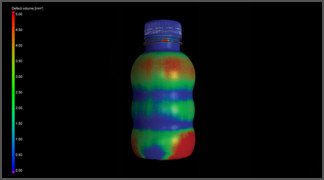

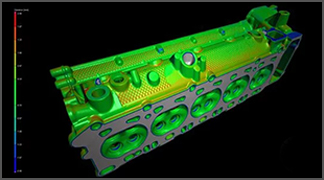

Computed tomography has played a pivotal role in Non-Destructive Testing (NDT) for the inspection of samples, parts, and assemblies manufactured from a wide range of materials. As CT Scanning is an X-Ray technology, the lower the density the material the easier it is to penetrate the object. As the density of the product being inspected increases, higher energies are required to properly penetrate the product. The downfall to higher energies is that the scan resolution quickly decreases the higher the energy goes.

This is where an experienced and highly diverse Industrial CAT scan lab can work with the customer to identify the best method of inspection to meet the reasons behind inspecting the sample. If the sample cannot be scanned in its entirety, section scanning or region of interest scanning could be a possibility depending on the geometry of the product. if the part can be cut up micro-CT scanning on a lower powered higher resolution system could be an option for providing critical insight that is needed.

You have reached our knowledge page on

CT scanning by material.

( CLICK TABS EXPAND )

High Density Materials (Iron, Steel, Cobalt, Inconel, Copper, Nickel)

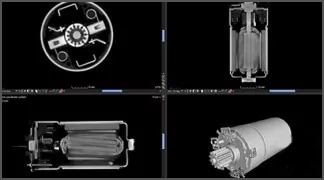

Higher density materials as noted in the original paragraph can be difficult to properly inspect. Materials such as iron, steel, stainless steel, cobalt, Inconel, copper, nickel, or mixed material assemblies with these components imbedded within them pose a challenge when inspection with CT Scanning is required. Usually, a high level of interaction with the imaging lab is required in these cases for the objectives to be properly met.

Extremely high-density materials such as tungsten, lead, silver, gold, and platinum are virtually impossible to inspect with traditional x-ray CT as these materials have x-ray defeating properties and are used as targets or shielding with computed tomography. Where the energy can be increased to penetrate the components, usually the spot size becomes so large the results are not able to meet the inspection requirements. When this happens usually alternative inspection methods are considered outside of x-ray computed tomography.

Medium Density Materials (Plastic, Ceramic, Carbon Fiber, Aluminum, Magnesium, Titanium)

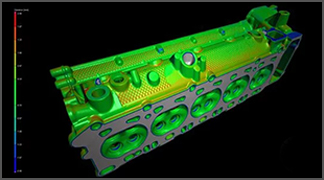

Medium density products such as plastics, ceramics, glass, porous filters, carbon fiber, and low-density alloys such as aluminum, magnesium, and titanium scan very well with computed tomography. Challenges arise when the object is manufactured of a flat geometry causing un-uniform x-ray pathlengths to occur during the scanning process. Depending on the application the product can be scanned in its entirety with geometry variations identified upfront or scanned in sections based upon the project requirements.

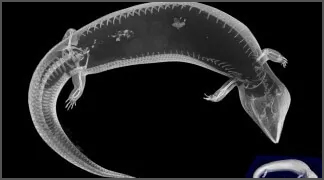

Low Density Materials - (Organic, Silicone, Rubber)

![]()

Products of low density have their own challenges as sometimes the subtle variations in material density is not able to be separated or viewed due to changes in grey scale values during imaging. Typically, variations of at least .25g/cc in density can be visualized and variations of .5g/cc or larger have enough information for physical boundaries to be confirmed. These low-density materials include as organic samples, silicones, and rubber. In addition to density challenges, fixturing or methods to hold the sample during the scanning process can become a challenge for repeatability and vibration. Very subtle changes in movement can severely impact the scan quality by blurring the images. Depending on the project requirements an experienced imaging lab can either overcome this or develop a method with the customer that works best for both parties.